Nesting façade: biodiversity through digital façade technology

A 3D-printed façade prototype has been developed at the Technical University of Munich that creates habitats for urban birds and small animals—while also improving the microclimate.

The project combines innovative digital technologies with ecological responsibility, making the city a better place to live for both humans and animals.

The nesting façade is an example of how architecture can actively contribute to species protection and sustainable urban development. Made from recyclable clay using robotically controlled printing processes, the modules can be flexibly adapted to different animal species and location conditions.

“The digital method is adaptive: it can be adapted to different locations and animal species.”

Julia Larikova

The city as a living space—for everyone

The loss of biodiversity and diversity in global animal populations, together with climate change, poses a threat to our ecosystems. This development is closely linked to the anthropocentric orientation of technology and architecture in the last century. Building envelopes were designed primarily for people and energy efficiency, but rarely with animals in mind.

At the same time, European cities are facing a major wave of building renovations. The Chair of Digital Fabrication at the Technical University of Munich (TUM) sees this as a dual opportunity: Renovation can contribute not only to climate protection but also to strengthening biodiversity in urban areas—provided ecological aspects are considered from the outset.

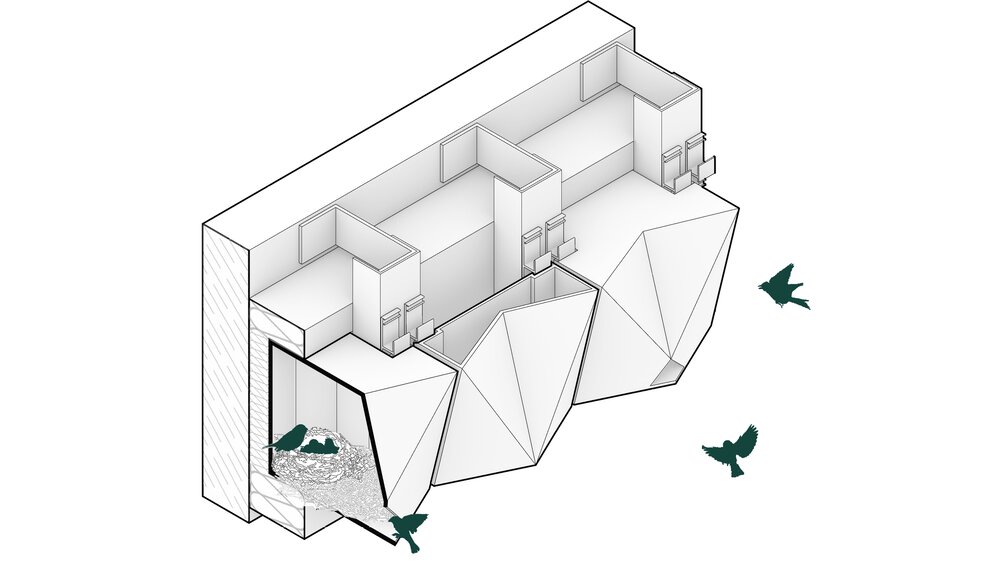

With the “Nesting Façade,” a novel prototype has been developed that intelligently combines ecological function with architectural design. The digitally designed and 3D-printed clay modules specifically integrate nesting and shelter spaces for birds and small animals. Their geometries respond to site-specific parameters such as solar exposure or wind pressure and contribute to improving the microclimate through self-shading.

Animal Aided Design

The scientific foundation for this approach is provided by the concept of Animal Aided Design (AAD). Here, animal species are not considered as an afterthought, but as “users” of architecture from the very beginning. “We work with specific biological parameters, such as nest size, orientation, or distance,” explains project lead Julia Larikova. The current installation includes three typical urban inhabitants: the house sparrow, the black redstart, and the hedgehog. Their specific needs were directly integrated into the geometry, positioning, and depth of the modular façade elements. The distribution of nesting opportunities on the façade was determined using digital planning and climate data simulations. In the upper section of the prototype, nine nesting sites for a colony of house sparrows were integrated. Six spatially separated nesting spots for the territorial black redstarts are strategically distributed across the façade. At the base of the building, five shaded ground-level elements provide sheltering retreats for hedgehogs.

In addition to species-appropriate design, the microclimate was also taken into account. The angular geometries of the front surfaces were modelled using climate simulations to create differentiated self-shading. Each element has an individual depth that is tailored to the local solar radiation. As a result, the building envelope not only cools the nesting chambers, but also reduces the overall heating of the façade surface. This is an important contribution to thermal comfort for humans and animals in rising summer temperatures.

3D Printing with Clay

The fabrication is carried out using a robotically controlled clay 3D printer. “Clay has many advantages: it’s natural, recyclable, durable, and has a positive climatic impact. And it’s harmless to many animal species,” explains Larikova. The printing process used a chamotte-containing mixture with around 40% recycled content from shredded ceramic waste.

The development of the geometries is based on self-programmed digital design tools. “We use existing tools like Rhino or Grasshopper for visualization, but the actual logic of form generation is created in Python. This allows us to translate biological and climatic parameters directly into geometry.” In this way, modules with specific depth, orientation, and opening size are created that adapt to the needs of different animal species and the site-specific conditions. A particular challenge was the deformation of the clay during drying. “It took almost two years to control the deformations through material adjustments and optimized printing paths.” The final prototype consists of 85 individually printed tiles, each taking about 1.5 hours to print. Printing was done with a robot-supported extrusion unit, drying took place under laboratory conditions, and the elements were fired twice to ensure weather resistance.

The developed 3D-printed elements are compatible with standardized, ventilated façade systems. This facilitates integration into existing renovation projects and allows for easy maintenance or targeted replacement of individual modules. Specific areas can be selectively designed with these elements—for instance, where ecological hotspots are to be created or where many people gather. Another topic currently occupying the researcher is certification. “Current standards don’t account for digitally fabricated building products. We are working with partners like MPA and TÜV Süd to develop realistic assessment frameworks. The goal is to simplify the approval process for such systems in the future without compromising on functionality or design freedom.”

Anyone who is curious can view the prototype at the Feierwerk Südpolstation site in Neuperlach. This collaboration with a public center increases the visibility of the approach and informs the public. The prototype is also being used for scientific monitoring: during the summer, its microclimatic properties are measured, and the behavior of species is observed over a period of at least three years.

The prototype is a collaboration between the Chair of Digital Fabrication and the Chair of Terrestrial Ecology at the Technical University of Munich, as part of the EU project ECOLOPES. The project is supported by the Foundation for Species Protection and Technology (Stiftung Artenschutz und Technik), the industry partner Tonality GmbH, and Feierwerk Südpolstation.

Project data:

Project Team:

Chair of Digital Fabrication:

Prof. Dr. Kathrin Dörfler, Julia Larikova, Niklas Ebert, Yaxi Wang

Chair of Terrestrial Ecology:

Prof. Dr. Wolfgang Weisser, Dr. Fabio Sweet

Technical University of Munich

Image credit: Julia Larikova