Circular, scalable and cheaper construction? It can be done.—Interview with Anke Parson, urban beta

If we remove reusable components from traditional property financing and finance them independently of the building, we will be able to offer much more favourable rental models in future—for residential construction, but also for other building typologies.

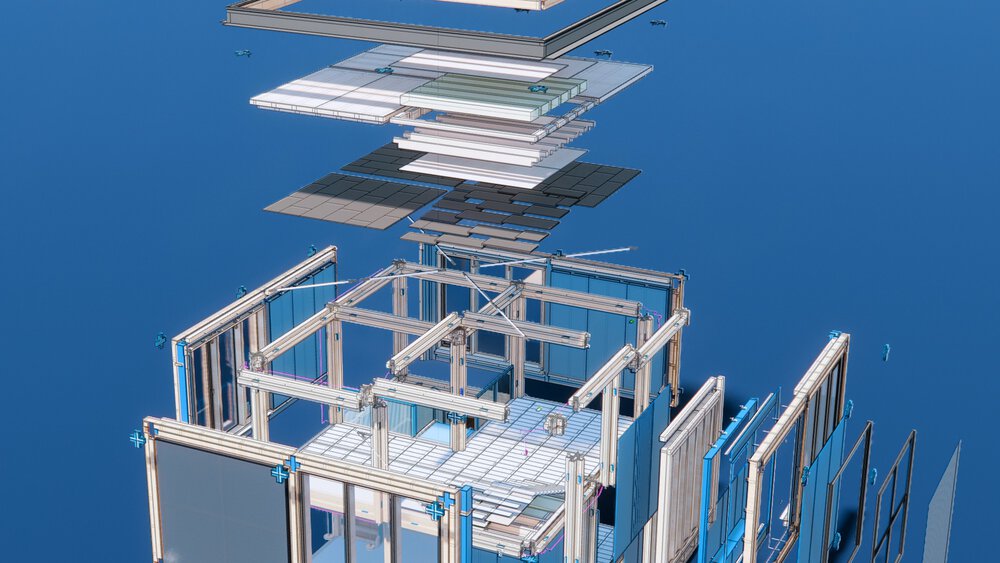

The BetaPort construction system is not a modular construction method, but an elementised construction system consisting of reversible elements. Specially developed nodal points connect beams and columns in a rigid frame system with a grid of 5.40 x 5.40 metres. The resulting skeleton can be filled with different elements in a modular fashion - open, closed, as a small unit or complex structure, from material to TGA, depending on use. This creates room systems that are scalable and adaptable and can grow and shrink with their users. And even more interesting: As a rental model, true to the motto Building-as-a-Service, the individual elements can be returned to the cycle up to ten times.

Time to talk to Anke Parson from urban beta about the future of construction and new business models.

Urban beta is not a module builder or property developer, but a tech company—what's that all about?

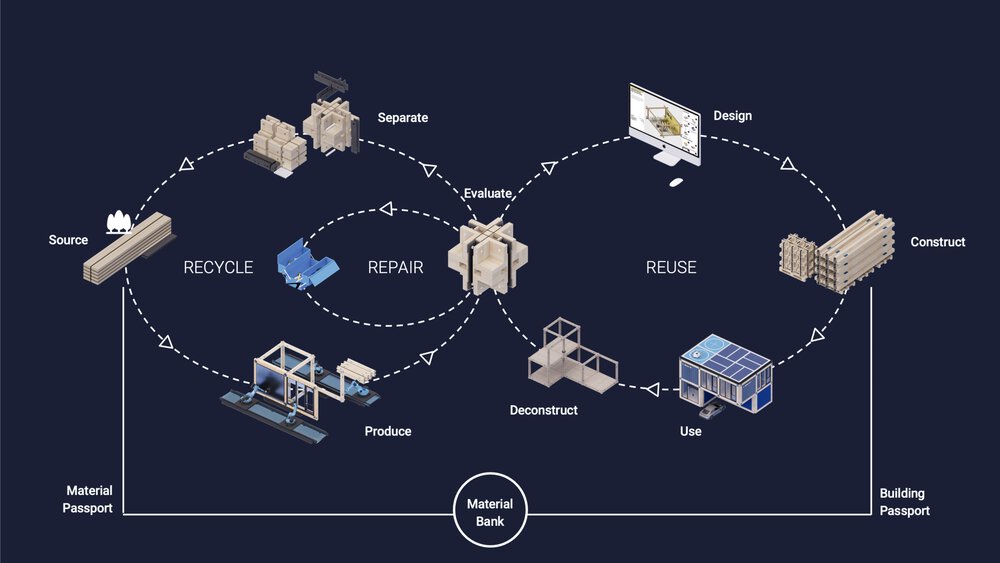

Anke Parson: On the one hand, our digital production chain utilises the potential of timber construction through AI-supported planning tools and an Industry 4.0 production approach that combines predictive planning and prefabrication with intelligent material processing. But we go one step further with our Design for Disassembly approach. Every wall, floor and ceiling element is designed for multiple life cycles and can be separated by type. This requires tested material partnerships to ensure high quality, but also digital infrastructure to guarantee complete traceability of the materials used in the components, as well as compliance with ecological standards and legal requirements. Tracking via RFID chips creates a component ecosystem that uses the connected database to provide detailed information about the design and use of materials in the components, including their location and maintenance cycles. In the end, it's all about the added value of the individual components.

This means that the materials end up back in the cycle as resources and not as waste. What are the limits of the system?

Anke Parson: Theoretically and practically, we are open to all materials in the partnerships we enter into with regard to expansion. However, the most important requirement is that we only work with partners who can close the loop with us, i.e. we are talking about single-origin designs, recycling and take-back systems for our own products at the end of their life cycle. This starts with flooring and extends to plug & play plugs for lights and heating systems, which are removed from one building and reinstalled in the next.

The only inflexibility we have is the grid. This sets us apart from the industry, which promotes customised production with its robotic systems. But does that really always have to be the case? If each module has its own window size, the idea of reusing it countless times fails because the components are too individualised and were only made for one location.

Part of your mission statement is to maintain the value of the components. At the Learning Hub in Leipzig, you offered the system as a rental model—why is that unusual?

Anke Parson: It's not enough for us to believe in the reuse of our components, there needs to be a different discussion about the value of resources. At the moment, building financing is linked to a structure that is connected to the ground and amortised over a period of twenty years. In fact, after amortisation, the material is now waste. In times of resource scarcity, this is a total waste. If you look at the price increases of certain materials and raw materials, there would even be an increase in value = return over the financing period. What makes it complex for us as BetaPort is the fact that we don't have to finance a building, but a bunch of loose components. We can already map this today using building resource passports and the first banks with a focus on sustainability are recognising the material value as an equivalent value in the financing. Our system already consists of over 50% reusable components, and we are aiming for 70-80% in the next 48 months. This means that the value can be retained over a longer period than the amortisation period. This also makes circular construction interesting from an economic perspective.

Of course, a high-quality component that is designed to be reused up to ten times costs more than a standard module, but the value retention creates a real impact. And this not only has an impact on the tenants of the building system, but also on the users, whose rent can be significantly reduced and who also spend time in healthy rooms. Here, too, there are various options—either via investors who invest in components as an asset class or via the industry partners who are involved in value creation. Next up is the EU taxonomy—so the next few years will definitely be exciting.

Background

Anke Parson is one of the co-founders of urban beta. Urban Beta creates scalable architecture systems on-demand with a strong focus on social inclusion, renewable energy and circular economy models.