Insights into the current research funding of Zukunft Bau

The construction industry is facing major challenges: increasing resource consumption, growing volumes of construction and demolition waste and the pressure to drastically reduce CO₂ emissions. At the same time, technological advances and ecological requirements are opening up new opportunities to develop more sustainable and efficient construction methods.

A large number of innovative research projects are dedicated to these topics.

Time for a look behind the scenes...

Bioconcrete

Fundamentals and process principles for the production of CO2-neutral and resource-efficient components

Researchers at the University of Stuttgart have developed a method for producing CO2-neutral concrete. Microbially induced calcite precipitation produces calcium carbonate as a binding agent that does not cause any process-related CO2 emissions. The results of the research project show that bioconcrete is a promising alternative to conventional concrete.

- University of Stuttgart, Institut für Leichtbau Entwerfen und Konstruieren (ILEK)

3D printing of reinforced concrete

Development of practice-orientated methods for 3D printing of the composite material reinforced concrete

The construction industry is facing a shortage of skilled labour, increasing demand for new buildings and low productivity increases. The research project ‘Additive Manufacturing of Reinforced Concrete’ (AMoRC) is investigating the 3D printing of reinforced concrete as an innovative solution. By developing a special print head and a welding device, the first functional reinforced concrete components could be additively manufactured. The results show great potential, but require further research to bring the technology to practical maturity.

- RWTH Aachen University,

Lehrstuhl und Institut für Massivbau (IMB)

Lehrstuhl und Institut für Schweiß- und Fügetechnik (ISF)

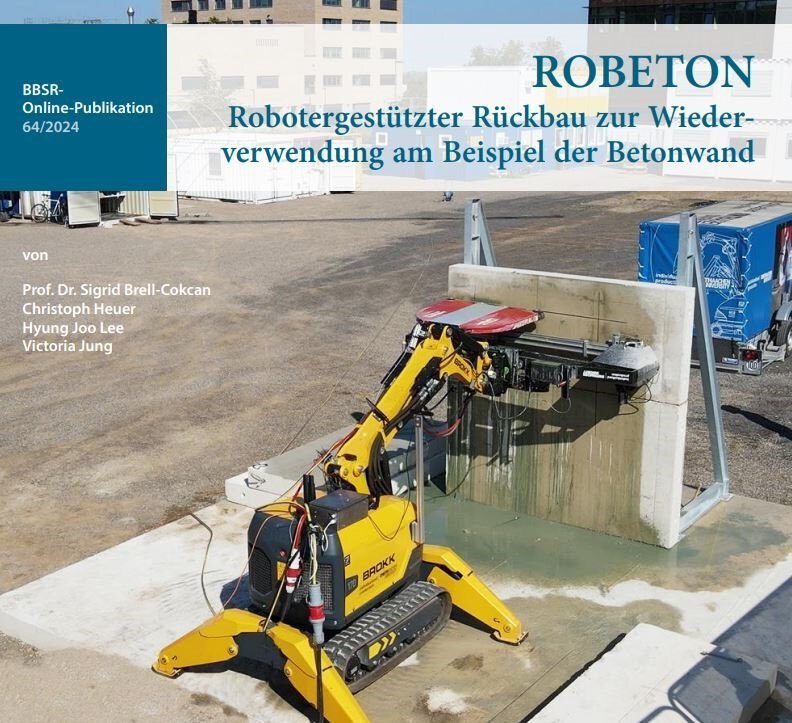

ROBETON

Robot-assisted demolition for reuse using the example of the concrete wall

The ‘ROBETON’ research project at RWTH Aachen University is developing a digitally controlled demolition robot that dismantles concrete components precisely and efficiently so that they can be reused. Based on a proven demolition machine, a new, semi-automated process is being created that integrates digital construction planning and intelligent control. Initial prototypes show an accelerated dismantling process, less strain on construction site personnel and a lower environmental impact. In addition to the reuse of concrete, the robot's flexible equipment enables a wide range of applications and promotes the acceptance of automation in the construction industry.

- RWTH Aachen, Lehrstuhl für Individualisierte Bauproduktion

Abbau Aufbau

Development of a cradle-to-cradle process for in-situ concrete elements

The ‘Abbau Aufbau’ research project at Berlin University of the Arts is investigating a sustainable construction method in which reinforced concrete components are carefully removed from demolished buildings and reused in new buildings. The focus is on in-situ concrete construction, the components of which can be reused using precise concrete sawing processes. In addition to ecological benefits, a digital planning tool and guidelines for practical implementation have been developed. A real laboratory to test this method in a test building is in preparation.

- Universität der Künste Berlin, Fachgebiet Konstruktives Entwerfen und Tragwerksplanung (KET)

CO2-neutral binders based on broken bricks and aspirated fillers

IAB Weimar is investigating the use of recycled brick dust and stone fillers as sustainable alternatives to cement. Initial results show that brick dust can be used as a cement substitute by activating and precisely separating it from construction waste to reduce CO₂ emissions and resource consumption in the construction industry. The successful separation of brick particles using magnetic separation and the experimental increase in reactivity emphasize the potential of these materials. However, further research is needed to optimize the processes for long-term and energy-efficient use.

- IAB – Institut für Angewandte Bauforschung Weimar gGmbH

rethinking wood

Wood particle-manufactured, recyclable components with high degrees of curvature

The rethinking wood research project at the University of Kassel is developing a sustainable process to utilise waste wood as a resource in the construction industry. Wood particles are moulded using biogenic binders and digital production techniques to create recyclable components with high degrees of curvature. These innovative elements can be used as insulation and acoustic solutions or in interior fittings and furniture construction. The reusability of the materials and the fact that no new machines are required creates an ecological and economic advantage that enables a closed material cycle.

- Universität Kassel, Fachbereich Architektur, Stadtplanung, Landschaftsplanung / Experimentelles und Digitales Entwerfen und Konstruieren

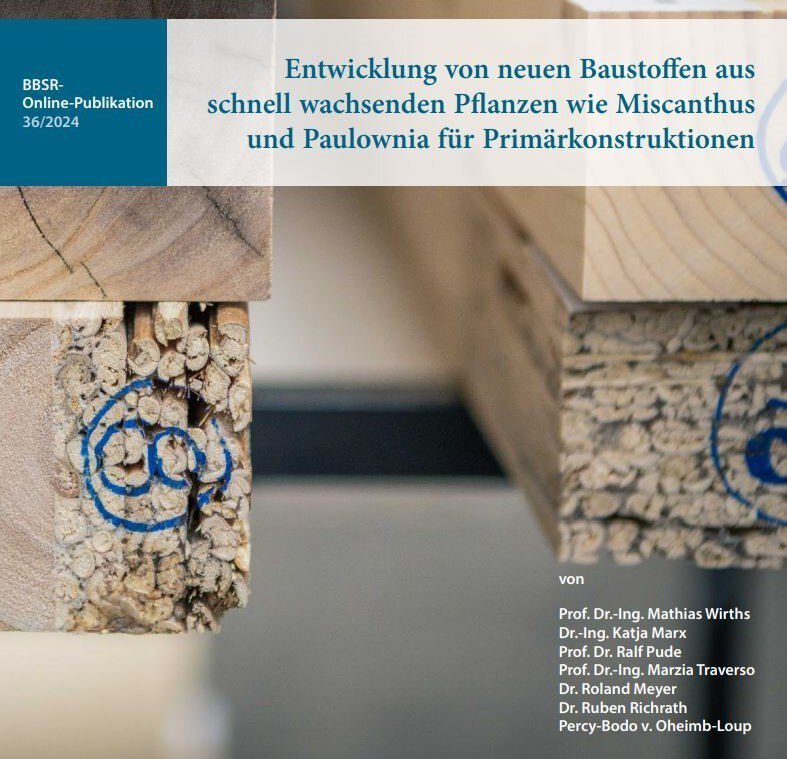

Development of new building materials from fast-growing plants such as Miscanthus and Paulownia for primary constructions

The research project is investigating the use of fast-growing plants such as Miscanthus x giganteus and Paulownia as sustainable building materials for load-bearing structures. Miscanthus, known for its high dry matter yield and CO₂ storage during growth, has been successfully processed into rod-shaped load-bearing elements that are equivalent to timber in terms of their bending strength. Initial approaches to material-compatible connections and construction methods open up new possibilities for the integration of renewable raw materials in the construction sector and contribute to CO₂ reduction.

- Alanus Hochschule, Alfter / Universität Siegen, Materialkundelabor des Departments Architektur

- Rheinische Friedrich-Wilhelm-Universität Bonn, Professur für Nachwachsende Rohstoffe

- RWTH Aachen, Institut für Nachhaltiges Bauen

- Creavis, Evonik Industries AG

Sustainable and reliable building with clay

Development of a semi-probabilistic safety concept for clay masonry affected by moisture

The research project ‘Sustainable and reliable building with clay’ investigates the load-bearing capacity of clay masonry taking into account material moisture and develops a semi-probabilistic safety concept for its design. Experimental analyses and modelling were used to create a load-bearing capacity model that integrates the influence of moisture on the strength and deformation properties of earth building materials. The results show that load-bearing earth masonry can be safely designed in accordance with the new normative regulations, while the research has made a significant contribution to the further development of relevant DIN standards.

- BBF | Beck Brinkmann Förster Beratende Ingenieure PartG mbB

Clay panel construction

Prefabricated load-bearing solid clay walls

The ‘Clay panel construction’ research project at Bauhaus-Universität Weimar is developing prefabricated load-bearing solid clay walls that enable sustainable and efficient construction. The combination of load-bearing layer and insulation layer achieves a high load-bearing capacity, good insulation values and resource conservation. Lightweight aggregates such as cork granulate and flax fabric improve the material properties, while innovative connections and surface treatments facilitate use in various construction projects. The prefabricated elements also fulfil modern requirements for fire protection and thermal insulation, repositioning clay as an ecological building material.

- Bauhaus-Universität Weimar

Upcycling of mineral construction and demolition waste (upMIN 100)

100 per cent substitution of natural aggregates and binders in reusable clay building materials

The ‘upMIN 100’ research project at the Technical University of Berlin is investigating the use of recycled construction and demolition waste for the production of earth building materials. The project is investigating whether the fine fractions (< 2 mm) that have been landfilled to date can completely replace natural aggregates and binders. The focus is on technical feasibility, the absence of pollutants and the ecological impact. The results have already been incorporated into existing DIN standards and open up new possibilities for sustainable construction through an improved recycling rate and the elimination of primary raw materials.

- Technische Universität Berlin

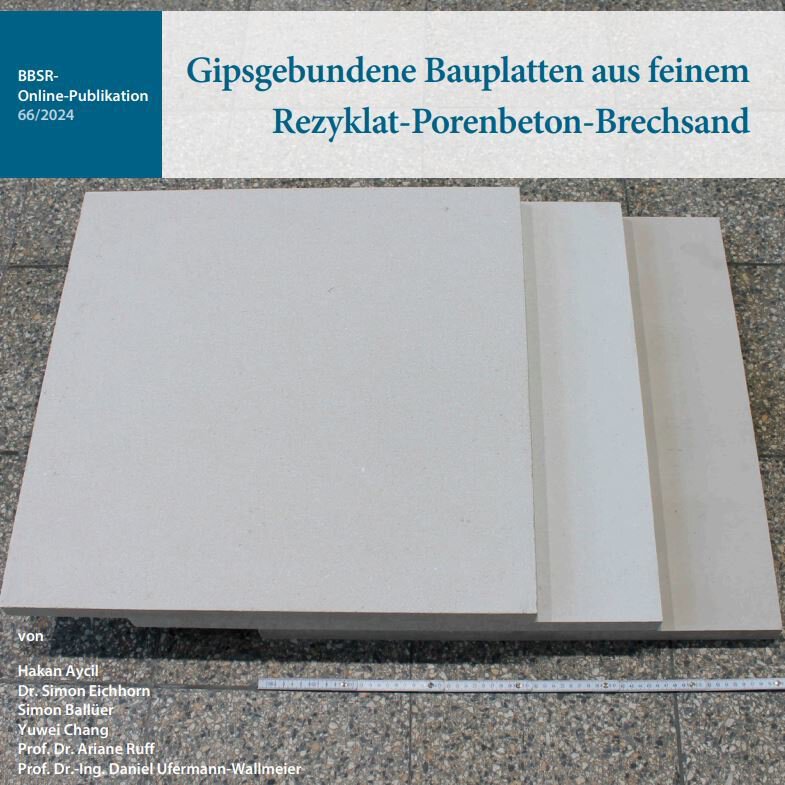

Gypsum-bonded building boards made from fine recycled aerated concrete crushed sand

The research project is developing gypsum-bonded building boards using crushed aerated concrete sand in order to create resource-efficient and high-quality alternatives to conventional gypsum building materials. Systematic laboratory developments and recipe optimisations are used to produce boards on a laboratory scale and test their industrial processing. The use of recycled gypsum and aerated concrete crushed sand minimises the proportion of gypsum and maximises resource efficiency, resulting in innovative building boards with sustainable potential.

- Leibniz-Institut für Werkstofforientierte Technologien – IWT, Bremen

- Hochschule Nordhausen/ThIWert, Nordhausen

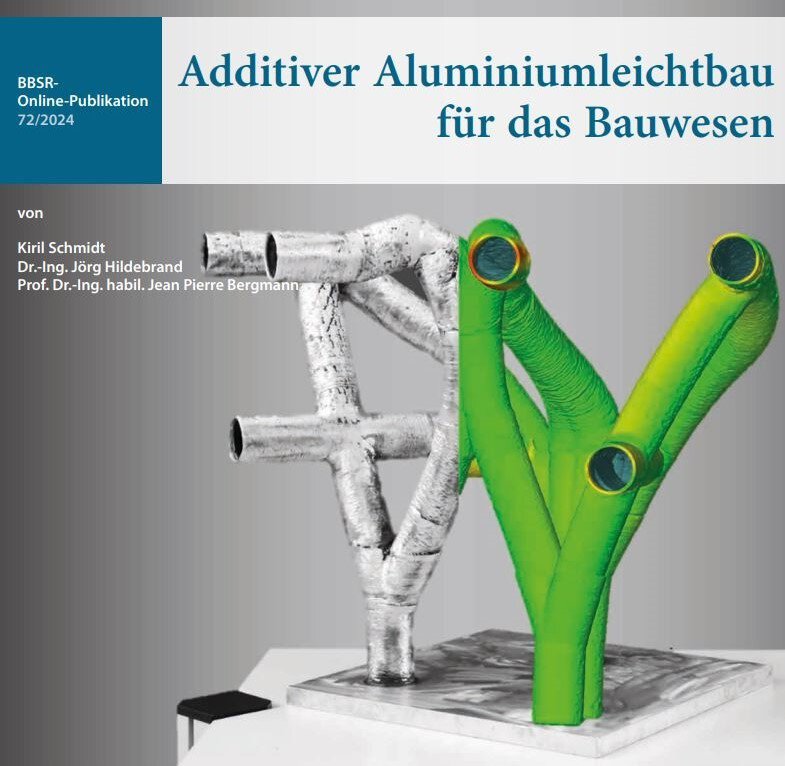

Additive lightweight aluminium construction for the construction industry

The research project at Ilmenau University of Technology is investigating the additive manufacturing of aluminium structures for lightweight construction in the construction industry. The DED-Arc process is used to develop topology-optimised connecting elements that impress with their material savings and high mechanical performance. An optimised AluTruss node shows significant improvements in weight, rigidity and load-bearing capacity. The results emphasise the potential of additive technologies for resource-efficient and resilient construction solutions.

- Technische Universität Ilmenau, Fakultät Maschinenbau, Fachgebiet Fertigungstechnik

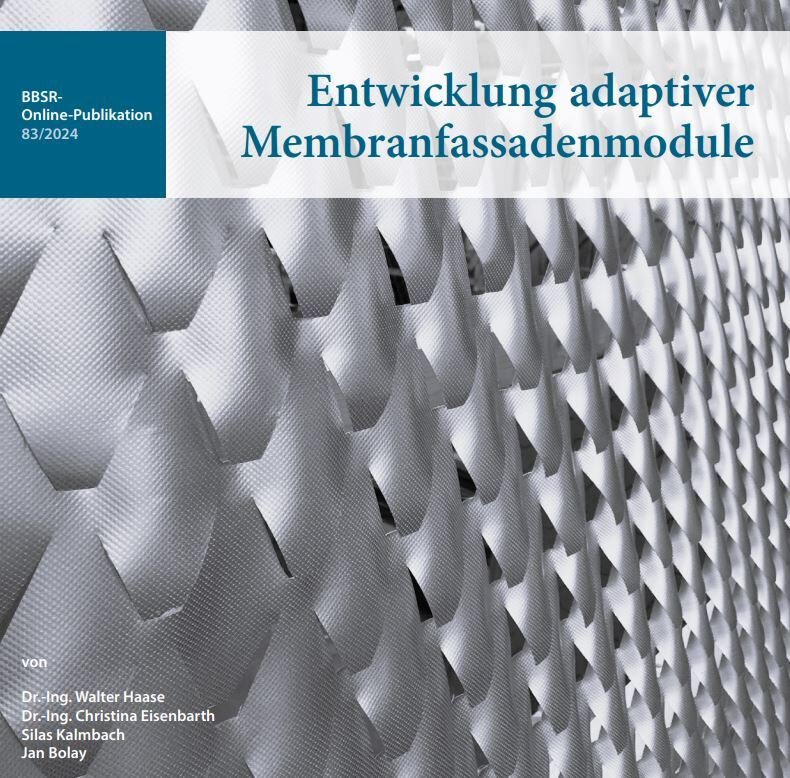

Development of adaptive membrane façade modules

The research project is developing innovative membrane façade systems that offer a resource-efficient alternative to conventional façades thanks to their low weight, high load-bearing capacity and complete recyclability. Multi-layered, individually functionalised modules are used to create opaque, translucent and transparent cladding solutions that integrate thermal, moisture, fire and noise protection as well as active sensor and actuator components. A modular aluminium frame system enables the flexible use of the textile façades, the practicality of which is being tested in a test building under real conditions and monitored over the long term.

- Universität Stuttgart, Institut für Leichtbau Entwerfen und Konstruieren (ILEK), Stuttgart